📘 Manufacturing #

Doing manufacturing in the Hive, starts with defining your Formula Template, which acts as the blueprint for production.

- A formula outlines the standard input materials (ingredients or components) required to produce a defined Yield Quantity (e.g., 20kg, 100 units, 50L) of finished product.

- The Yield Qty reflects the total output generated from one full formula cycle.

When it’s time to produce, you’ll create a Batch based on this formula.

- The batch specifies how much product you want to make.

- The system automatically scales all input quantities according to the batch size, using the original formula yield as the reference.

✅ Example 1: Cupcakes (Unit-Based Output) #

Product: Chocolate Cupcakes

Formula Yield: 24 cupcakes

Ingredients (per formula):

1.5 kg Flour

0.5 kg Cocoa Powder

Meaning:

This formula is designed to produce 24 cupcakes. If you want to produce 48 cupcakes, you would enter a batch size of 2. If you only want 12 cupcakes, you enter a batch size of 0.5.

| Batch Size | Final Output | Flour Needed | Cocoa Needed |

|---|---|---|---|

| 1 | 24 cupcakes | 1.5 kg | 0.5 kg |

| 2 | 48 cupcakes | 3.0 kg | 1.0 kg |

| 0.5 | 12 cupcakes | 0.75 kg | 0.25 kg |

✅ Example 2: Dough (Weight-Based Output) #

Product: Bread Dough

Formula Yield: 10 kg

Ingredients (per formula):

6 kg Flour

4 kg Water

Meaning:

This formula is designed to produce 10 kg of dough. If you want to produce 20 kg, enter a batch size of 2. For 5 kg, enter a batch size of 0.5.

| Batch Size | Final Output | Flour Needed | Water Needed |

|---|---|---|---|

| 1 | 10 kg | 6.0 kg | 4.0 kg |

| 2 | 20 kg | 12.0 kg | 8.0 kg |

| 0.5 | 5 kg | 3.0 kg | 2.0 kg |

🔁 Summary: Yield vs Batch #

Formula Yield = “Blueprint” or baseline output of a recipe (per 1 batch).

Batch Qty = How many times you want to produce the formula.

System will auto-scale ingredients based on

Formula Yield × Batch.

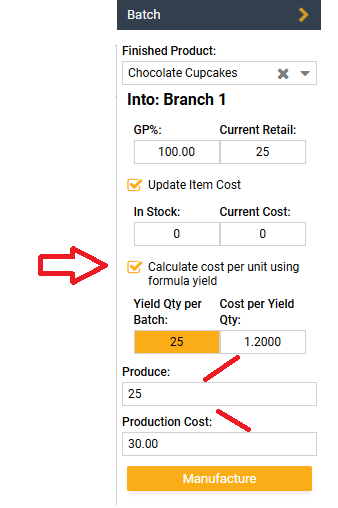

Pro Tip – Yield Cost #

“Calculate cost per unit using formula yield”

Tick if this item is sold in units. Cost will be calculated per unit based on the formula’s yield.

✅ What does “Calculate cost per unit using formula yield” mean? #

This setting controls how the cost of a batch is calculated, based on whether you’re producing units (e.g., cupcakes) or bulk weight (e.g., dough in kg).

🧁 If You’re Producing Units (e.g., Cupcakes) #

Tick this box.

The formula yield defines the cost per unit.

Example:

Formula yields 24 cupcakes using R100 worth of ingredients.

That means each cupcake costs R100 / 24 = R4.17.

If you produce a batch size of 2 (48 cupcakes), total cost = 2 × R100 = R200.

This gives you cost per unit, which is critical if you’re selling individual items.

🍞 If You’re Producing Bulk (e.g., Dough in kg) #

Leave this box unticked.

The entire batch yield is the produced quantity (e.g., 10 kg dough).

The full formula cost is the cost of the entire batch.

Example:

Formula yields 10 kg of dough using R50 worth of ingredients.

If batch size is 0.5, you produce 5 kg, costing R25.

This is useful when the product isn’t sold per unit, but per kg or as input for another process.

#

Lets get started on actual example #

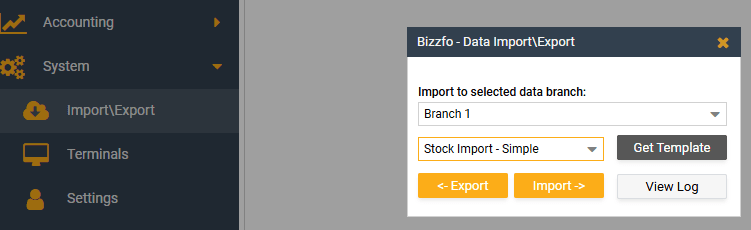

The above mentioned items can be imported into your hive. Open the hive and select “Get Template”

Download templates for

- Stock Import – Simple

- Manufacture

Inspect these files and remove items not needed.

Once ready, select the corresponding option, Stock Import – Simple or Manufacture and then click on the “Import” Button to upload these files.

Quick how to video